Overview of Aluminum Alloy Door & Window Profile Extrusion

Aluminum alloy door and window profile extrusion is a hot extrusion process that shapes aluminum billets into profiles with desired cross-sections. This technology enables production of complex-profile, high-precision door/window components, serving as the core manufacturing technique for modern architectural fenestration.

Keywords: aluminum profile extrusion, window aluminum profiles, aluminum extrusion process, architectural aluminum profiles, aluminum door/window fabrication

Extrusion Process Flow for Aluminum Door & Window Profiles

1. Raw Material Preparation

- Selection of 6xxx series alloys (e.g., 6063, 6061)

- Aluminum billet diameter matching profile dimensions

- Homogenization heat treatment for billets

Keywords: 6063 aluminum alloy, aluminum profile raw material, billet processing, aluminum alloy heat treatment

2. Die Design & Manufacturing

- Design of porthole dies or flat dies based on profile cross-section

- Use of H13 hot-work tool steel for dies

- Precision machining and heat treatment for dies

Keywords: aluminum extrusion dies, porthole die design, H13 die steel, profile die machining

3. Extrusion Process

- Heating: Billets heated to 450-500°C, dies to 400-450°C

- Extrusion: Aluminum forced through dies under pressure

- Quenching: Immediate air/water cooling after exiting die

- Pulling: Stretcher alignment for profile straightness

Keywords: aluminum profile extruder, hot extrusion technology, profile quenching, extrusion pulling system

4. Post-Extrusion Processing

- Stretching & Straightening: Eliminate bending/twisting

- Cut-to-Length: Precision cutting for fenestration requirements

- Aging Treatment: T5/T6 heat treatment for strength enhancement

- Surface Treatment: Anodizing, powder coating, or electrophoretic coating

Keywords: profile straightening, aging treatment, aluminum surface treatment, anodized aluminum profiles

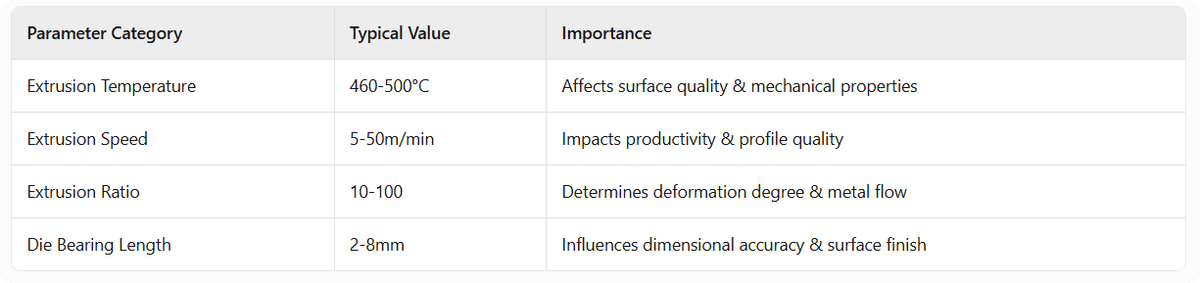

Critical Technical Parameters for Profile Extrusion

Parameter CategoryTypical ValueImportanceExtrusion Temperature460-500°CAffects surface quality & mechanical propertiesExtrusion Speed5-50m/minImpacts productivity & profile qualityExtrusion Ratio10-100Determines deformation degree & metal flowDie Bearing Length2-8mmInfluences dimensional accuracy & surface finish

Keywords: extrusion parameters, aluminum extrusion temperature, extrusion speed control, die bearing design

Equipment for Aluminum Profile Extrusion

Main Equipment Components

- Extrusion Press: 800-3600 ton capacity based on profile size

- Billet Heater: For aluminum billet heating

- Die Heater: Maintains optimal die temperature

- Puller: Ensures profile straightness

- Cooling Bed System: For profile cooling & transfer

Keywords: aluminum profile extruder, extrusion equipment, billet heating furnace, profile pulling machine

Common Quality Issues & Solutions

1. Surface Defects

- Scratches: Poor die polishing or rough guides

- Blisters: Gas in billets or trapped air in container

- Black Lines: Aluminum sticking to die bearing

2. Dimensional Deviations

- Uneven Wall Thickness: Poor die design or misalignment

- Twisting: Insufficient pulling force or uneven metal flow

3. Mechanical Property Issues

- Low Strength: Improper aging or alloy composition deviation

- Insufficient Hardness: Inadequate quenching cooling rate

Keywords: aluminum profile defects, extrusion quality control, dimensional accuracy, aluminum strength improvement

Industry Development Trends

- Energy-Efficient Profiles: Multi-chamber thermal break designs

- Large-Section Profiles: For oversized door/window systems

- Smart Extrusion: Digital control for precision manufacturing

- Green Production: Energy reduction & waste minimization

- Composite Profiles: Aluminum-wood/plastic hybrid systems

Keywords: thermal break profiles, large aluminum sections, intelligent extrusion, eco-friendly aluminum, composite window profiles

Advantages of Aluminum Profile Extrusion

- High Productivity: Continuous high-speed production

- Design Flexibility: Complex cross-section capabilities

- Material Efficiency: 100% recyclable scrap

- Consistent Quality: High dimensional accuracy

- Superior Strength-to-Weight Ratio: Lightweight yet strong

Keywords: aluminum profile benefits, precision extrusion, aluminum recycling, lightweight strong aluminum

By optimizing aluminum door/window profile extrusion processes, manufacturers can produce high-quality fenestration components meeting diverse architectural requirements. With ongoing technological advancements and evolving market demands, aluminum profile extrusion continues to innovate, delivering superior products for the construction industry.